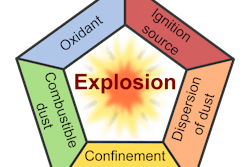

Zero-entrygrain bin policiesare rightfully in place tokeep workers safe around storage bins, but they don’t necessarily address the cause of many bin entries. One reason farmers and grain handlers wind up in grains bin is due to out-of-condition grain, not an abhorrence to safety policies.

Out-of-condition grain can cause mold, spoilage, hot spots, clumping and crusting. In turn, a leading reason for entering a grain bin is to restore the discharge or flow of the contents inside. If you see evidence of crusting on the surface or within a grain mass, or if the floor outlets are clogged,Purdue University recommends联系一位有经验的专业谷物萨尔瓦•ge service equipped to remove the out-of-condition grain.

All too often, however, when presented with crusting, the urge to finish an important task overrides safety recommendations and policies. Since Purdue University has been trackinggrain engulfment incidents and fatalitiesin the 1970s, dozens of tragedies have resulted from people trying to unplug a bin and not following proper lockout/tagout procedures, and then suddenly — grain begins to flow again, drawing the bin’s inhabitant down with the mass.

The importance of the relationship between grain quality and safety can never be overstated. Preventing hot spots and grain spoilage reduces hazards at grain handling operations, and ultimately, save lives.

That’s why leading grain science researchers at Purdue,Iowa State UniversityandKansas State Universityhave been proponents of a quality management strategy called SLAM for the last three decades. SLAM stands for Sanitation, Loading, Aeration and Monitoring, and has been widely taught as a part of an Integrated Pest Management program for stored grains.

Grain quality education opportunity

This month,Feed & Grainwill host thewebinarSLAM 360: The full circle of grain quality preservation, featuring presenterDr. Dirk Maier, director of theISU Kent Corp. Feed Mill and Grain Science Complexand professor for the Department of Agricultural and Biosystems Engineering; Department of Animal Science at Iowa State University.

In the first installment of this multi-part webinar series, you’ll hear why grain quality can never be improved once it’s harvested from the field, but it can be maintained. You’ll also gain knowledge on how to properly sanitize grain bins, clean grain before binning and protect it from weather, pests, self heating, molds and mycotoxins.

The webinar will broadcast live at 1 p.m. Central on Wednesday, March 29. Registration and other details can be foundhere.