A Solids Weigh Feeder is a feed device that not only controls the flow of material (for batching or blending), but it also gravimetrically weighs the material so that the feeding of product is done is an extremely accurate manner.

It can be difficult to know whether your application warrants the use of a Solids Weigh Feeder or not. While the setup and use of these devices can be quite simple, there are multiple ways of setting them up and utilizing their features and benefits, depending on the application. Therefore, a few of the most common Solids Weigh Feeder applications are outlined below.

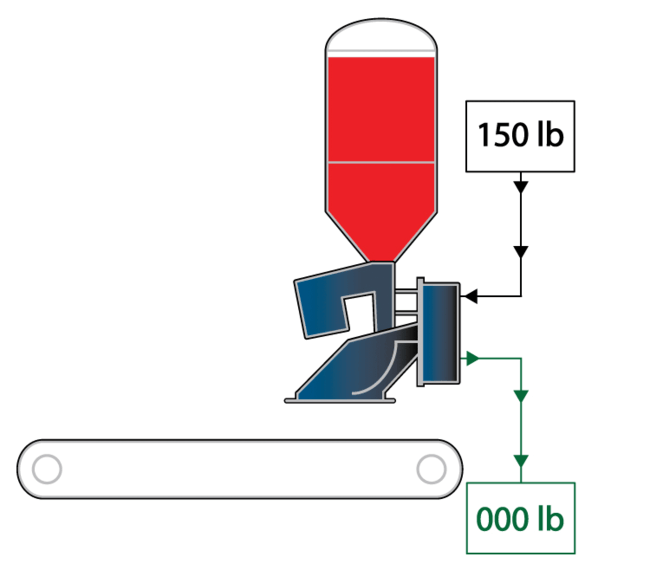

Batching

A Solids Weigh Feeder can be used for simple and accurate measurement and control of a single product. In such a scenario, a singleCentriFeedercould be utilized and equipped with standard electronics and a color touchscreen HMI. This simple but effective setup can be used to batch granular materials into your process. A weight set point and a flow rate are entered into the CentriFeeder. When the feeder is started, it will maintain the entered flow rate. Once the weight set point (total) is reached, the feeder will automatically stop the flow of material for extremely accurate batches.

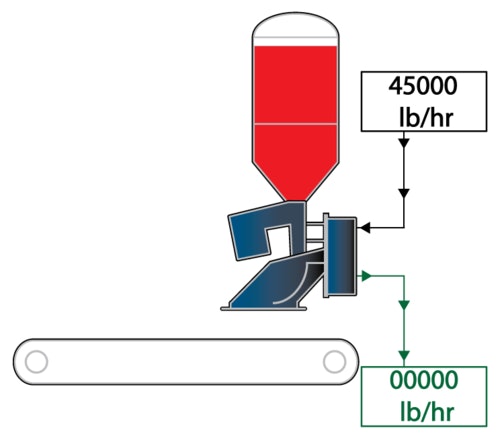

Flow Control

For blending applications, or applications that are continuously running, a Solids Weigh Feeder can control based on flow rate only. Again, a single CentriFeeder would be utilized and equipped with standard electronics and a color touchscreen HMI. This simple but effective setup can be used to continuously feed a controlled flow rate of material into your process. A flow rate set point is entered into the feeder. Once the feeder is started, it will modulate the rate of the material feed (opening and closing the feed gate) to maintain the desired flow rate. The feeder will then shut off again once it receives a signal that your process has shut down, or that you are out of product.

Blending

A Solids Weigh Feeder can also be used for multiple product blending in continuous processes. In this scenario, multiple CentriFeeder devices each with standard electronics and a color touchscreen UI, would be utilized. In such an application, the separate units can be used independently, meaning that the flow rate can be adjusted for each unit. Rather than entering a flow rate and total/batch setpoint, you would only enter a rate setpoint and the feeder will control to that flow rate setpoint. As an additional option, the independent feeders can be tied to a master controller (or PLC controller) that will send remote set points down to the individual feeders making them versatile for easy changing of recipes or blend percentages.

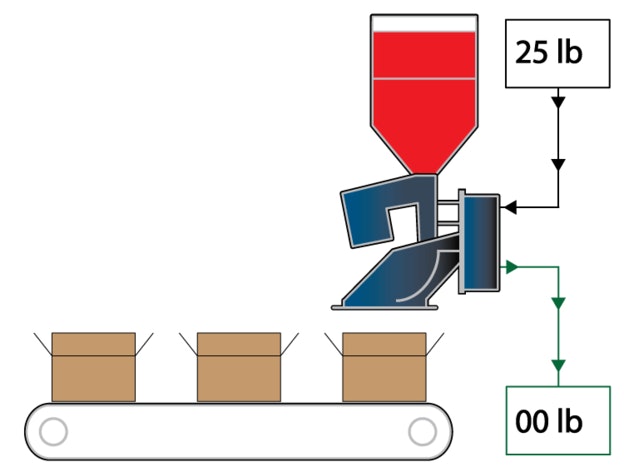

Filling

As a variation on the idea of using a Solids Weigh Feeder for batching, it can also be utilized for filling applications. For filling applications, from 10 lb containers up to vehicle filling, the CentriFeeder line of feeders will offer a very quick and very accurate fill. To utilize these devices for filling, you can enter a desired flow rate and a total set point (the fill amount for each container). You then press the start button, and the feeder will maintain the desired flow rate until the fill total has been met. The feeder will then shut off, stopping flow of the material. The fill accuracy is typically within +/-0.50% when filling containers from 10 lb to as large as railcars or trucks. Typically, custom fill screens and software are available depending on the filling application.

Solids Weigh Feeders are great for a variety of applications where processes need streamlined or controlled to a greater degree.

The CentriFeeder line of feeders provides accurate, real-time flow measurement, as well as near perfect control of flow rate and total. Whether batching single products, filling containers, or blending multiple products together, the CentriFeeder line of feeders can help.